Overview

Shanghai Jixiang Building Materials Group was founded in 2004. Its headquarter is located in Pinggao Square, Songjiang District, Shanghai. It has established large-scale production bases in Fengxian, Shanghai and Xinzheng, Henan, with a total area of more than 300 mu. We have 16 advanced aluminum plastic composite production lines and 6 large-scale aluminum coating production lines.

MORE +

Product

Adhering to surpassing traditional ways of thinking and development models, taking a differentiated competitive route as the strategic starting point, and promoting the concept of innovative products through providing multiple creative methods, with a forward-looking perspective and the role of a promoter, we are committed to the advancement of China's metal building materials industry.

MORE +

Engineering

Following the high-quality development model of accumulation and gradual progress, our products have gained more and more excellent reputation in the market and industry.

MORE +

Marketing

Shanghai Jixiang Building Materials Group has always adhered to a flexible marketing strategy, actively carried out social centered marketing planning work, and implemented foreign sales strategies. Exporting to countries and regions such as Russia, Germany, Canada, the United States, India, Australia, etc., to meet high-end demand from various foreign countries.

MORE +

News

Shanghai Jixiang Building Materials Group was founded in 2004. Its headquarter is located in Pinggao Square, Songjiang District, Shanghai. It has established large-scale production bases in Fengxian, Shanghai and Xinzheng, Henan, with a total area of more than 300 mu. We have 16 advanced aluminum plastic composite production lines and 6 large-scale aluminum coating production lines.

MORE +

Sustainability

Through long-term social responsibility management and practice, Jixiang has consciously undertaken historical missions, fulfilled social responsibilities, and promoted sustainable development of the enterprise, gradually forming its own unique social responsibility management model - mission led social responsibility management.

MORE +

Contact

The world of auspiciousness, the auspiciousness of the world, Shanghai Jixiang Building Materials Group has the courage to assume social responsibility, become stronger and larger enterprises, and serve society with patriotism and love for the people.

MORE +

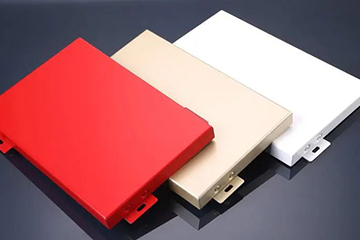

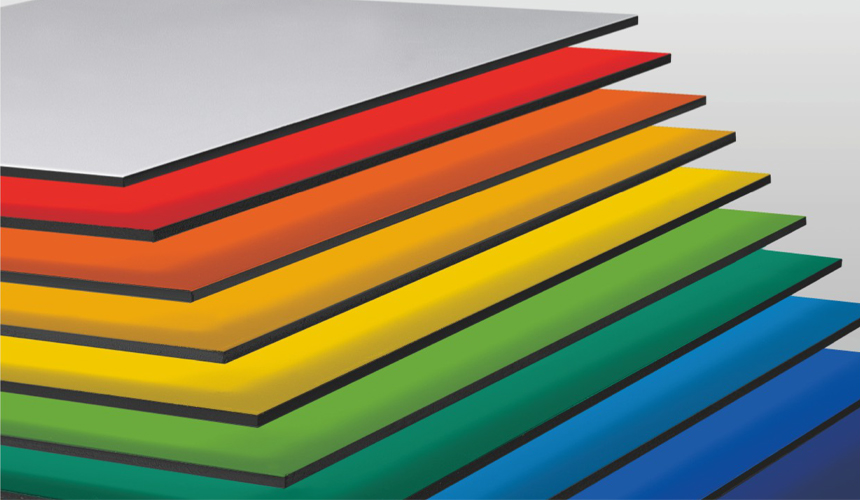

Aluminum plastic plate series

The series of aluminum plastic panels produced by Shanghai Jixiang Building Materials Group include brands such as ZWM, Jixiang Jiamei, Jixiang Four Seasons, Shenzhou Jixiang, Jinmu, and Xiqing. The aluminum plastic panel series is divided into five categories: interior wall panels, exterior wall panels, wood grain panels, granite grain panels, and fire resistant panels, with over a hundred different specifications and colors of panels. The Baoyi aluminum plastic plate series uses high-quality rust resistant alloy plates and high-strength polyethylene core plates. The coating used is currently advanced fluorocarbon resin coating, which is completely produced according to relatively standard processes.

Aluminum plastic composite board, also known as aluminum plastic board, is a new type of material that is made of aluminum plate that has undergone surface treatment and is coated with baking paint, with polyethylene polypropylene plastic mixed as the core layer, and processed and compounded through a series of processes.

The aluminum plastic plate was first developed and produced by ALUDINGEN in Germany, and then improved by FORKEN and Alcoa. After the 1990s, the production quality gradually stabilized and reached a high level. As the aluminum plastic plate is composed of two materials (metal and non-metal) with different properties, It not only retains the main characteristics of the raw materials (metal aluminum, non-metallic polyethylene plastic), but also overcomes the shortcomings of the raw materials, thus obtaining many excellent material properties, such as luxury, colorful decoration, weather resistance, corrosion resistance, impact resistance, fire prevention, moisture prevention, sound insulation, insulation, and seismic resistance; The characteristics of lightweight, easy processing and forming, and easy handling and installation have opened up broad application prospects for aluminum plastic panels.

|

|

Economy |

|

|

Durability |

|

|

Flatness |

|

|

Lightness |

|

|

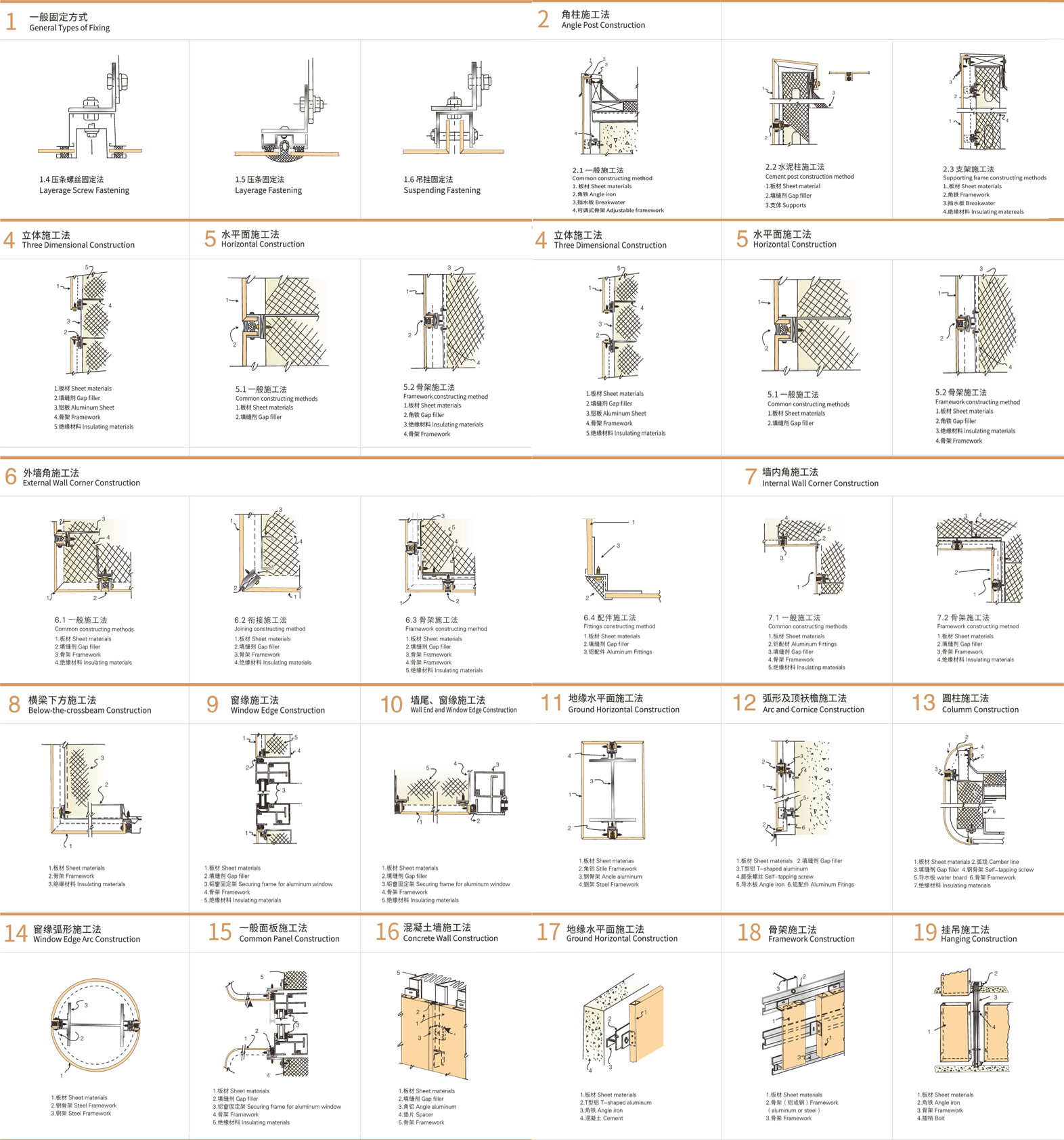

Constructability |

|

|

Fire resistance |

|

|

Design performance

|

|

|

Environmentally |

Aluminum plastic board is a good material that is easy to process, shape, and assemble, and is also an excellent product for pursuing efficiency and fighting for time. It can shorten the construction period and reduce costs. The equipment of a typical sheet metal or woodworking factory can easily complete its processing and assembly work.

Aluminum plastic panels can:

1. Cutting, cutting, slotting, band saw, vertical saw, locking hole, machining countersink.

2. Cold bending, cold folding, cold rolling.

3. Riveting, screw bonding, welding, clamping or bonding.

4. Spray painting, screen printing, sign boards, and advertising sign boards.

• Curtain wall decoration/interior decoration/ airports/docks/stations/subways/shopping malls/hotels/hotels/entertainment venues/high-end residences/villas/office buildings

• Large advertising signs/display windows/roadside newspaper booths/book stalls/telephone booths/traffic guard booths/roadside gas stations

• Indoor walls/ceilings/compartments/kitchens/bathrooms/wall skirting

• Shop decoration/interior shelves/cabinets/pillars/furniture/train/car/ship/passenger car decoration

• Renovation and renovation of old buildings

• Purification and dust prevention engineering

Jixiang Serve You

innovation driven

Building a Competitive Building Materials Group