Overview

Shanghai Jixiang Building Materials Group was founded in 2004. Its headquarter is located in Pinggao Square, Songjiang District, Shanghai. It has established large-scale production bases in Fengxian, Shanghai and Xinzheng, Henan, with a total area of more than 300 mu. We have 16 advanced aluminum plastic composite production lines and 6 large-scale aluminum coating production lines.

MORE +

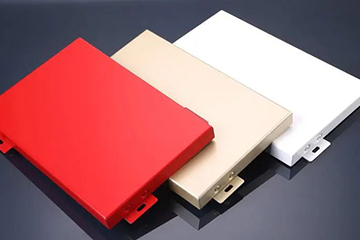

Product

Adhering to surpassing traditional ways of thinking and development models, taking a differentiated competitive route as the strategic starting point, and promoting the concept of innovative products through providing multiple creative methods, with a forward-looking perspective and the role of a promoter, we are committed to the advancement of China's metal building materials industry.

MORE +

Engineering

Following the high-quality development model of accumulation and gradual progress, our products have gained more and more excellent reputation in the market and industry.

MORE +

Marketing

Shanghai Jixiang Building Materials Group has always adhered to a flexible marketing strategy, actively carried out social centered marketing planning work, and implemented foreign sales strategies. Exporting to countries and regions such as Russia, Germany, Canada, the United States, India, Australia, etc., to meet high-end demand from various foreign countries.

MORE +

News

Shanghai Jixiang Building Materials Group was founded in 2004. Its headquarter is located in Pinggao Square, Songjiang District, Shanghai. It has established large-scale production bases in Fengxian, Shanghai and Xinzheng, Henan, with a total area of more than 300 mu. We have 16 advanced aluminum plastic composite production lines and 6 large-scale aluminum coating production lines.

MORE +

Sustainability

Through long-term social responsibility management and practice, Jixiang has consciously undertaken historical missions, fulfilled social responsibilities, and promoted sustainable development of the enterprise, gradually forming its own unique social responsibility management model - mission led social responsibility management.

MORE +

Contact

The world of auspiciousness, the auspiciousness of the world, Shanghai Jixiang Building Materials Group has the courage to assume social responsibility, become stronger and larger enterprises, and serve society with patriotism and love for the people.

MORE +

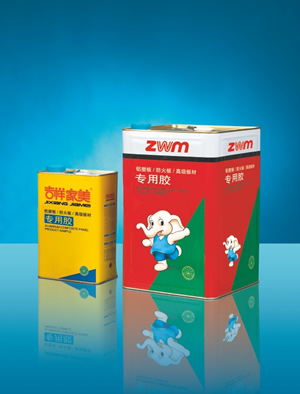

Silicone adhesive series

This product is a widely used and durable acidic adhesive used for glass sealing and building materials. The product is suitable for assembly of glass, aluminum alloy, ceramics, fiberglass, plastic steel, non oil wood, etc. Powder sprayed aluminum alloy must be thoroughly cleaned of the wax coating with a solvent.

Product features:

Made of DuPont chloroprene rubber from the United States, through plasticization, pre crosslinking treatment, and homogenization. This product is light yellow and semi transparent, with a light and elegant odor, high initial adhesion, and high final strength. It can also be used under cold conditions, not frozen at -20 ℃, and can be cold cured. Good aging resistance. This product belongs to the decorative adhesive series and is a must-have product for high-end and high-grade decoration and decoration of hotels, hotels, villas, etc.

Applicable scope:

Used in fields such as decoration, furniture manufacturing, automotive interior, advertising, etc. It can be used to paste the same and different materials such as aluminum plastic board, fireproof board, wood, leather, furniture, metal, rubber, plastic, etc.

Construction reference:

Clean, dry, and roughen the adhesive surfaces of the two bonded materials, and determine the amount of adhesive application based on the pore density of the bonded board. Usually, one application is sufficient. For special situations or materials that require two coats, wait for one coat to dry before applying the second coat. The adhesive should be evenly applied and allowed to air for 5-50 minutes to form a dry film (referring to non wire drawing or non stick to the hand), and the adhesive position should be adjusted once, After fitting, use a rubber hammer to evenly hammer and apply pressure and exhaust from the inside out. Apply glue and pressure evenly in place to avoid foaming and edge opening; If dilution is required, please use our company's special diluent, and use a brush or special scraper for gluing tools.

Kind reminder:

1. When bonding dense materials such as aluminum plastic panels and fireproof boards, it is necessary to drill several breathable holes on the substrate to avoid bulging after bonding.

2. When used outdoors, the bonding seam should be sealed with glass adhesive to prevent water leakage and adhesive opening.

3. It should be used in a ventilated and dry construction environment, and should not be in contact with children.

4. This product is flammable and should be stored in a cool and dry place, away from sparks, heat sources, and avoid direct sunlight exposure.

Characteristics:

Jixiang neutral silicone weather resistant sealant is a single component, high modulus, neutral curing material that can be extruded for use under a wide range of climatic conditions and quickly react with moisture in the air. It solidifies into a durable, high-performance, and highly deformable silicone sealant that can resist natural erosion such as ozone, ultraviolet radiation, rainwater, frost, etc; Mainly used for weather resistant sealing applications of common curtain walls. It has excellent adhesion to most building materials.

Main purpose:

Non structural adhesive sealing for glass curtain wall assembly; Waterproof sealing of outdoor building installations; The bonding of most building materials such as aluminum, steel, ceramic tiles, plastics, etc; Make final modifications and seals when assembling the product.

Color:

Standard colors include black, stone gray, light gray, deep gray, apricot white, porcelain white, or various colors required by the user.

Packaging specifications:

Net capacity 300 milliliters hard support or 590 milliliters composite aluminum box soft packaging.

Storage:

Under storage conditions below 27 ℃ and relative humidity below 50%, the shelf life is 9 months from the production date.

Jixiang Serve You

innovation driven

Building a Competitive Building Materials Group